Complete Guide to Sewage Treatment Process, Benefits, and Importance

In today’s world, where sustainability and environmental responsibility are at the forefront, Sewage Treatment Plants (STPs) play a critical role in treating wastewater before it is released back into the environment. Whether for residential, commercial, or industrial use, understanding the working of sewage treatment plants is vital for eco-friendly living and compliance with environmental norms.

In this blog, we will explore everything you need to know about STPs — their definition, process, components, types, advantages, and why investing in a sewage treatment plant is a wise decision for any establishment.

What is a Sewage Treatment Plant?

A Sewage Treatment Plant is a facility designed to treat and purify domestic and industrial wastewater (commonly known as sewage), removing contaminants and making it safe to release into the environment or reuse for non-potable purposes like gardening, cooling, or flushing.

Also known as a Wastewater Treatment Plant (WWTP), it processes sewage water using physical, chemical, and biological methods.

Why is a Sewage Treatment Plant Important?

✅ Environmental Protection

Untreated sewage can contaminate rivers, lakes, and groundwater, harming ecosystems. STPs prevent pollution by removing harmful substances from wastewater.

✅ Public Health

They eliminate pathogens, bacteria, and viruses, reducing the risk of diseases and ensuring safe water disposal.

✅ Water Conservation

Treated water can be reused for landscaping, construction, or flushing, reducing the demand for fresh water.

✅ Legal Compliance

Municipal bodies and environmental agencies mandate STP installations for large housing societies, hotels, hospitals, factories, and commercial complexes.

How Does a Sewage Treatment Plant Work?

A typical sewage treatment plant goes through three major treatment stages:

1. Primary Treatment

This is the first phase where solid waste is removed from the sewage water.

- Screening: Large debris like plastics, cloth, and garbage are removed.

- Grit Removal: Sand, stones, and small particles settle.

- Sedimentation Tank: Heavier solids settle as sludge.

2. Secondary Treatment

Biological treatment to remove dissolved and suspended organic matter.

- Aeration Tank: Microorganisms (bacteria) break down organic matter with oxygen supply.

- Secondary Clarifier: Treated water and leftover sludge are separated.

3. Tertiary Treatment (Optional)

This advanced treatment step ensures the water is almost free of any impurities.

- Filtration: Using sand or activated carbon filters.

- Disinfection: Chlorination, UV, or ozonation to kill any remaining pathogens.

- Polishing: Final stage to meet strict water discharge standards.

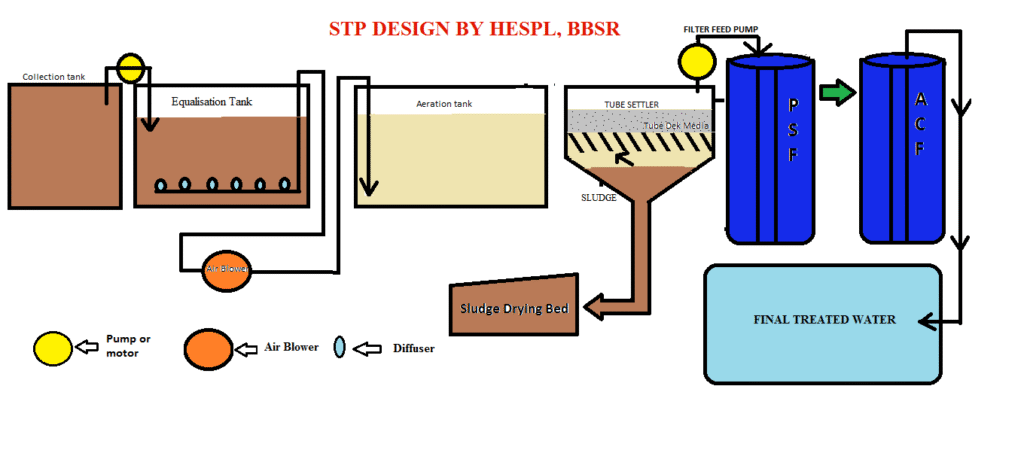

Components of a Sewage Treatment Plant

- Bar Screen Chamber

- Oil & Grease Trap

- Equalization Tank

- Aeration Tank

- Clarifier or Settling Tank

- Sludge Handling Unit

- Disinfection Unit

- Treated Water Tank

Types of Sewage Treatment Plants

1. Conventional Activated Sludge Process (ASP)

Widely used in urban STPs, this process uses aerobic bacteria to digest organic pollutants.

2. Moving Bed Biofilm Reactor (MBBR)

Uses plastic carriers for bacterial growth, offering efficient biological treatment with low footprint.

3. Sequential Batch Reactor (SBR)

Performs treatment in batches — useful for plants with variable inflow.

4. Membrane Bio-Reactor (MBR)

Combines biological treatment with membrane filtration for high-quality treated water.

5. Extended Aeration

A variation of ASP, used in small to medium setups for better sludge handling.

Benefits of Installing a Sewage Treatment Plant

✅ Reduces water pollution

✅ Promotes water recycling

✅ Saves operational costs in the long term

✅ Complies with environmental laws

✅ Increases property value

✅ Protects public health and ecosystems

Ideal Applications of STP

- Residential Apartments & Gated Communities

- Hotels, Resorts, and Hospitality Sector

- Hospitals and Educational Institutions

- Industries and Factories

- Commercial Complexes and Malls

- Government Buildings and Offices

Cost of Sewage Treatment Plant in India

The cost varies depending on:

- Capacity (KLD – Kilo Litres per Day)

- Type of STP (MBR, SBR, MBBR, etc.)

- Automation Level

- Location and Installation Area

Approximate Price Range: ₹5 lakh to ₹50 lakh+

Operating Cost: ₹0.5 to ₹2 per liter depending on electricity, manpower, and maintenance.

Government Norms & Regulations in India

According to the Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCBs), installation of STPs is mandatory for:

- Housing societies with more than 20,000 sq. m area

- Hotels with more than 100 rooms

- Industries discharging trade effluent

Non-compliance can lead to penalties and even shutdowns.

Maintenance of Sewage Treatment Plant

Regular maintenance ensures smooth functioning:

- Periodic cleaning of tanks

- Monitoring bacterial activity

- Checking pumps, blowers, and filters

- Regular sludge removal

- Record-keeping and compliance reporting

Conclusion

A Sewage Treatment Plant is not just a legal requirement but a responsibility toward the environment. With increasing urbanization and water scarcity, STPs provide a sustainable solution to manage and reuse wastewater effectively.

If you are planning to install an STP for your society, commercial property, or industry, always choose a reliable and experienced supplier who offers installation, operation, maintenance, and technical support.

FAQs about Sewage Treatment Plants

🔹 What is the lifespan of an STP?

Usually, 15–25 years with proper maintenance.

🔹 Can STP treated water be used for drinking?

No, it is not recommended for drinking, but safe for non-potable uses like gardening or flushing.

🔹 How much space is needed for an STP?

Depends on capacity; a 100 KLD STP may require 800–1000 sq. ft. area.

Tags: sewage treatment plant, STP process, wastewater treatment, water recycling, eco-friendly living, sewage water purification, MBBR, SBR, STP in India, treated water use, CPCB norms